Milling

Quickly generate a tool path with extensive control to meet the individual requirements of each part.

Production milling

Full functionality of the NC machine and maximization of workshop productivity

3-axis milling

A powerful series of 3-axis cycles for machining complex free-form parts.

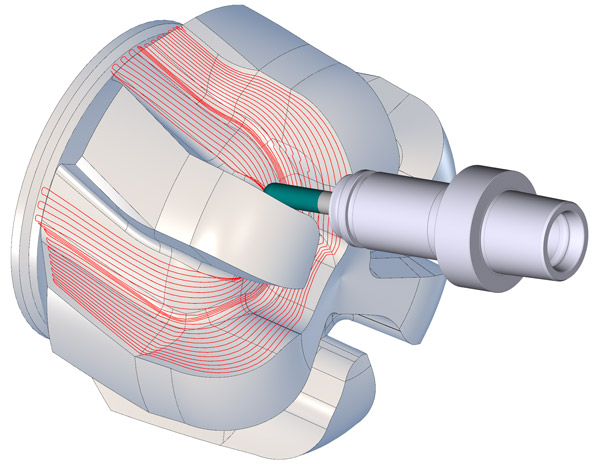

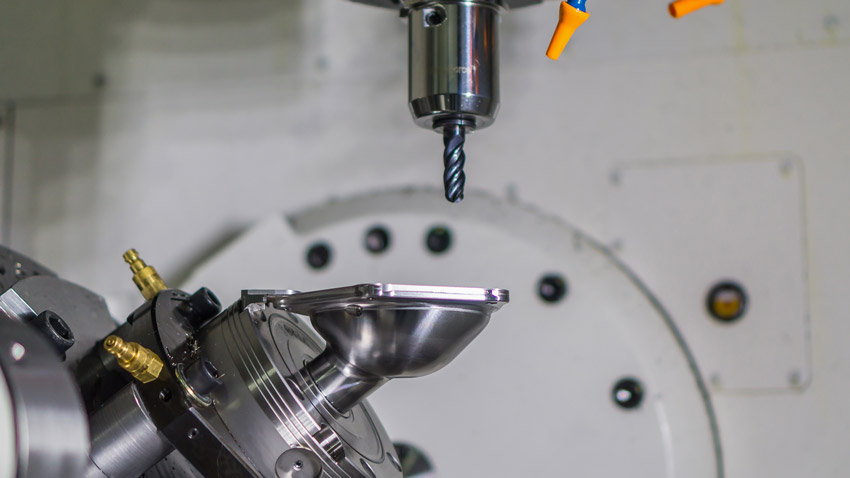

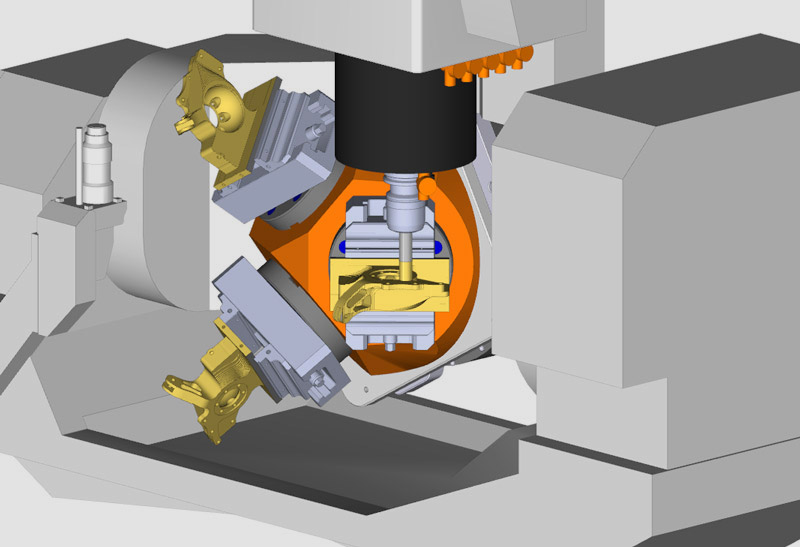

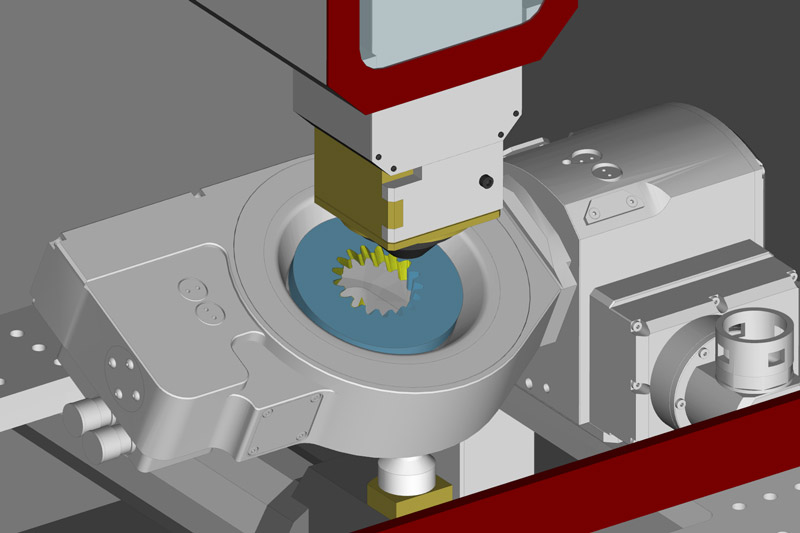

5-axis milling

3D machining of complex shapes in 5 simultaneous axes, with complete tool control and high-speed machining.

High speed machining

ProfitMilling ensures a 75% reduction in cycle time and a 500% increase in tool life.

Turning

Turning and part handling cycles for all types of turning, milling or CNC multifunctionality

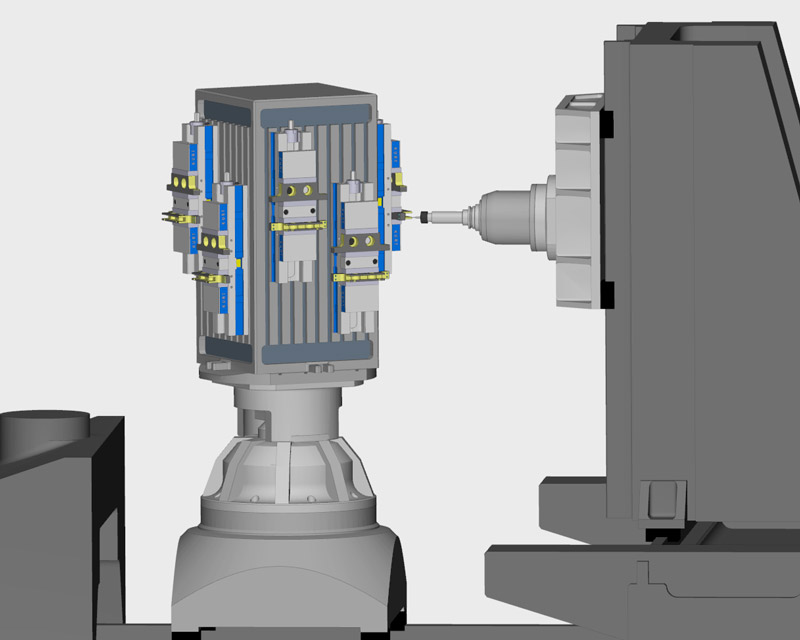

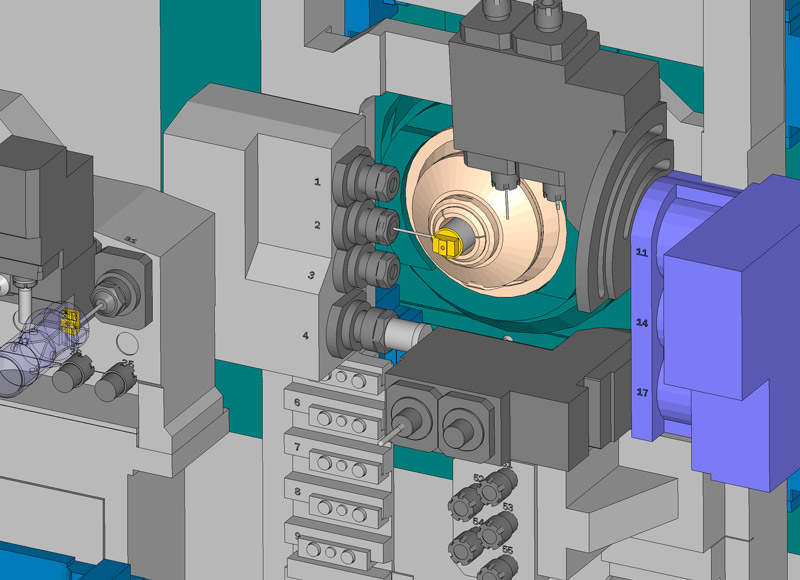

Multitasking machining

Powerful programming, optimization and simulation for multi-function and multi-channel machines

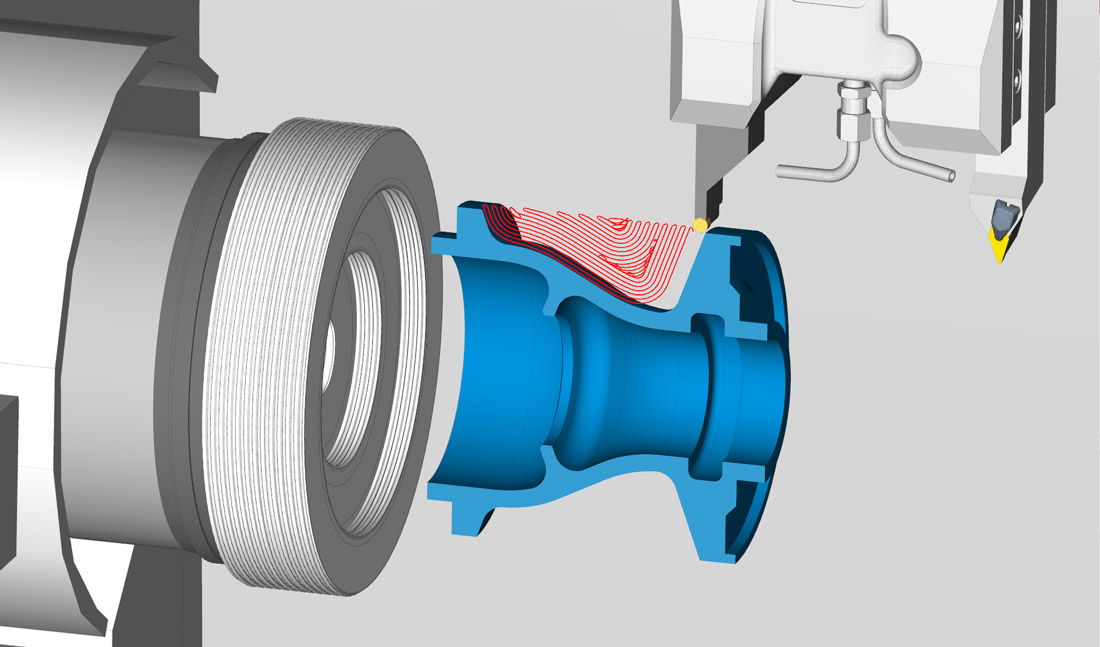

Bar turning

Adapted to numerical turning centers: programming, cycle optimization and complete machine and process simulation.

High-speed turning

ProfitTurning ensures a 25% reduction in cycle time and a 300% increase in tool life.

Wire electric discharge machining

Innovative solutions optimized for wire EDM machines

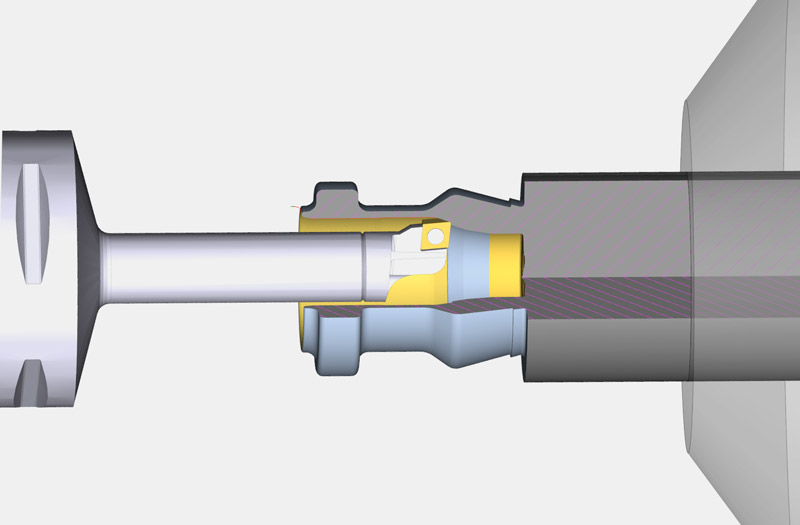

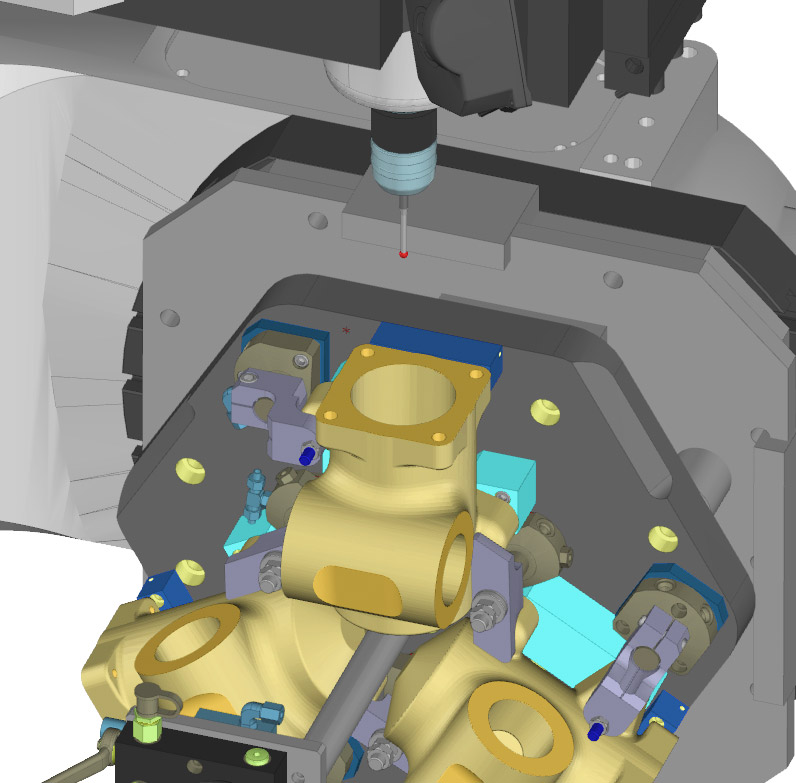

Probing

A powerful series of probing cycles that combines machining and inspection into a single complete program.

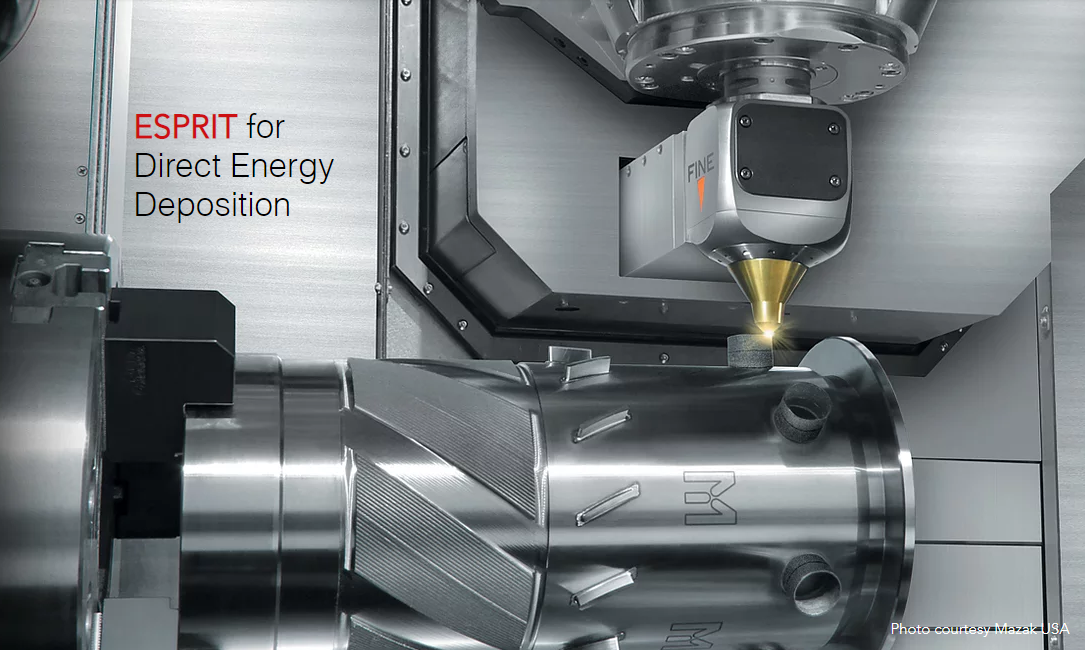

Additive for DED

Additive and subtractive programming in a single process